PVC Dual Pipe Extrusion Line

Pipe Diameter Range: Φ16 – Φ63

1. The PVC double-tube Dual production line has been developed based on the advanced technology of Western Europe. It can produce one out of two PVC pipes or even one out of four PVC pipes (small size only) at the same time;

2. Adopting unique screw design, the material in the barrel residence time is short, mixing and plasticizing effect is good;

3. Using high-quality gear box with beautiful appearance, smooth operation and low noise. Also it adopts vacuum exhaust system, which can remove the moisture and volatile gases in the material and improve the quality of the product;

4. One mould out of two or four tubes – production efficiency and output can be doubled, with independent control and convenient operation;

5. The main motor adopts variable speed governor, and the output torque of the motor is stable. The PVC conduit pipe production line is directly produced from powder materials, saving labor and energy, and has high production efficiency. The PVC conduit pipe is marked according to the pipe outer diameter. Φ16, Φ20, Φ32, Φ40 are the nominal outer diameters of the pipe. The inner diameter is different according to the different wall thickness.

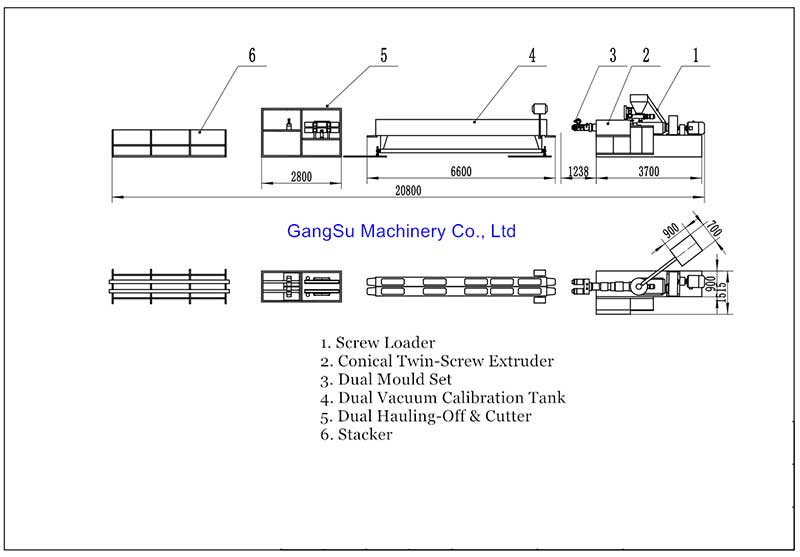

Layout:

Production Process Raw Material + Additive Preparation (Formula) → Mixing ( Mixer Unit) → Loading (Screw Loader) → Conical Twin-Screw Extruder → Dual Extrusion Mould → Dual Vacuum Calibration Tank → Dual Crawler Hauling-off Machine + Dual Lifting Cutter → Stacker → Finished product testing packaging

| Diameter(mm) | Φ16-40

Dual Line |

Φ20-63

Dual Line |

| Extruder Model | SJZ51/105 | SJZ55/110 |

| Motor Power | AC 18.5Kw | AC 22Kw |

| Capacity (Kg/h) | 80-120 | 120-180 |

| Line Length (m) | 18 | 18 |