PPR Pipe Extrusion Line

Pipe Diameter Range: Φ16 – Φ160

1. The line is mainly used for producing various diameters & wall thickness pipes, which are widely used in residential water supply systems, industrial water transport, compressed air transportation, etc. PPR pipes advantages: low cost, non-toxic, no rust, high temperature resistance, easy installation and so on.

2. The line is developed by absorbing both domestic and foreign advanced technology. Its key components such as screw and machine head are specially designed according to the characteristics of PPR. The control electric appliance adopts frequency conversion speed regulation, and the main electrical parts adopt imported brand-name products; the entire production line has the characteristics of high output, stable quality and small product error, and is the first-class equipment in the current plastic industry.

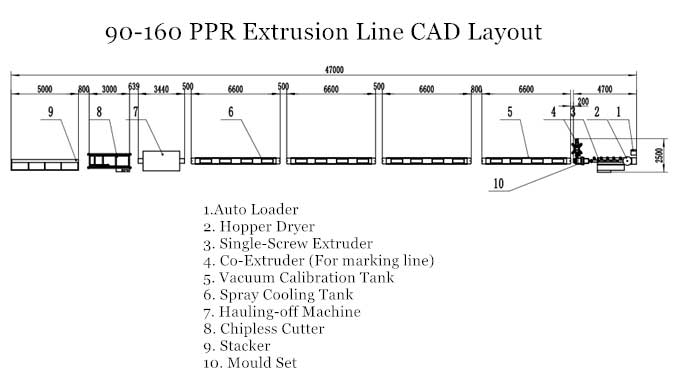

Layout:

Material + Color Master-batch → Mixing → Vacuum Loading → Raw Material Drying → Single Screw Extruder → Color Line Extruder → Mould → Vacuum Calibration Tank → Spray Cooling Water Tank → Crawler Haul-Off → Chipless Cutter → Stacker → Completed Product Inspection & Packaging

| Model | SJ65/33 | SJ75/33 | SJ90/33 |

| Pipe Diameter/mm | Φ16 – Φ63 | Φ75 – Φ110 | Φ110 – Φ160 |

| Screw Diameter /mm | Φ65 | Φ75 | Φ90 |

| Ratio( L/D ) | 33 : 1 | 33 : 1 | 33 : 1 |

| Screw Speed /r.min | 0-80 | 0-80 | 0-80 |

| Capacity /kg.h | 70-130 | 100-250 | 130-350 |

| Hauling Speed /m.min | 0-10 | 0-3 | 0-3 |

| Cutting Method | Chipless Cutting | Chipless Cutting | Chipless Cutting |

| Total Power /kw | 80 | 90 | 150 |