PERT Pipe Extrusion Line

Pipe Diameter Range: Φ16 – Φ32

1. The line is mainly used to produce PERT pipes. PERT pipe is a kind of non-cross-linked polyethylene pipe that can be used for hot water. It is a kind of medium-density polyethylene produced by special molecular design and synthesis process. It adopts the method of copolymerization of ethylene and octane to obtain unique molecular structure by controlling the number and distribution of side chains to increase the strength of PE pipes. PERT pipe can be applied for all levels of hot water pipes specified in ISO 10508.

2. The line uses a high-performance single-screw extruder. Its optimized design of the barrier screw and slotted barrel ensures a homogeneous melt and stable extrusion. The high-torque gearbox equipped with the extruder is fully capable of exchanging high back-pressure ratios when producing PERT. The mould used is a spiral head tailored to the material properties of PERT. Through the improvement of the machine head, the situation of melt fracture in the extrusion process is effectively avoided, and the surface finish of the PE-RT pipe is guaranteed to be high.

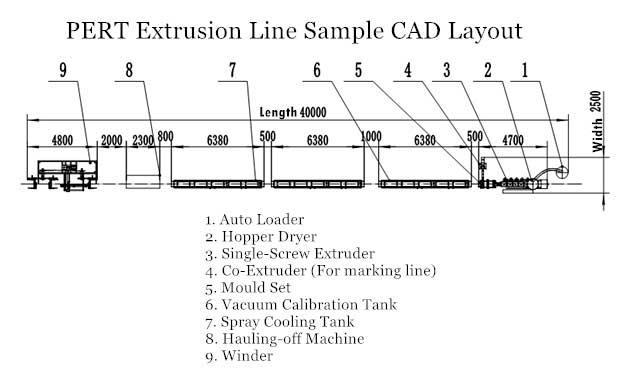

Layout:

Raw Material → Vacuum Loading → Raw Material Drying → Single Screw Extruder → Screw Mould → Vacuum Calibration Tank → Soaking Cooling Water Tank → Soaking Cooling Water Tank → Crawler Hauling-Off Machine → Winder → Finished product inspection and packaging

| Model | Pipe Diameter/mm | Extruder | Max. Capacity | Main Motor Power |

| GSPE-RT | Φ16 – Φ32 | SJ65/33 | 70-130Kg/h | 45Kw or 55Kw(AC) |